Hydrophilic Coatings

Non-ferrous metal

Functional surface treatment chemicals to create a paint base and add hydrophilicity and corrosion resistance to non-ferrous metal parts such as aluminium.

We have two types of hydrophilic coatings for heat exchangers : the pre-coating type for treating the aluminum plate for heat exchangers and the post-coating type for treating the heat exchanger itself.

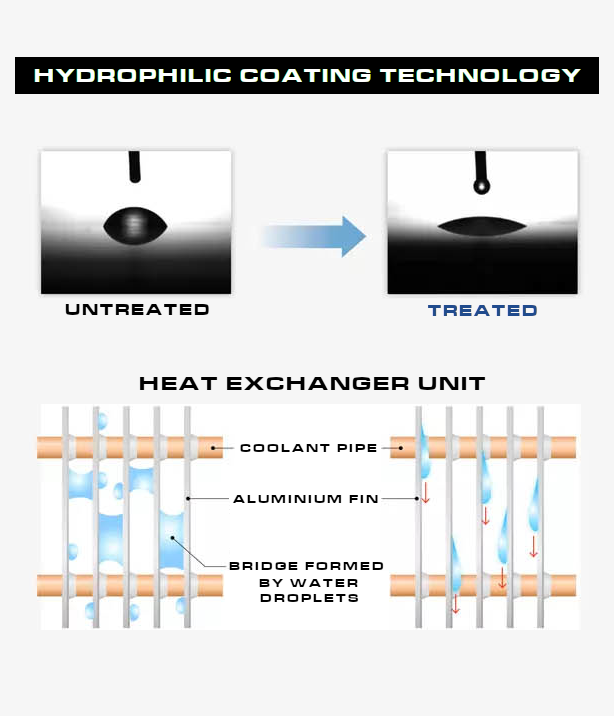

Our PALENE hydrophilic coatings prevent bridges of condensate between the fins by making the surface of the heat exchanger hydrophilic, which prevents the reduction of cooling efficiency.

The special resin provides good hydrophilicity and reduces odor from the evaporator with its low-adsorption property.

Rust prevention can be improved by using it with primer.

What is hydrophilic coating technology ?

A Hydrophilic Coating is a thin film that makes the surface of metal products hydrophilic.

Hydrophilic treatment of the surface of an air conditioner heat exchanger allows the dew condensation water generated during air conditioning to spread across the surface of the heat exchanger. This keeps the air flow in good condition and contributes to energy conservation.

Hydrophilic treatment can also impart functionality to maintain a comfortable living environment, such as low odor.

What are the key features ?

A film with high hydrophilicity retainability can be achieved by combining hydrophilic substances and optimally orienting them on the surface using cross-linking and intermolecular interaction.

The component resins can be selected depending on the required performance, such as low odor and resistance against indoor contaminants, to create added value.